|

Microprocessor based technology with multi channel based on potentiostat operations.

CD Tester or cathodic disbonding tester is designed to test and accurately determine the characteristics of insulating coating systems applied over steel material.

Highly recommended cathodic disbondment test equipment for paint, coating, rebar manufacturers and coating plants.Applied cathodic protection potentials may cause loosening of the coating, beginning at holiday edges.

Spontaneous holidays may also be caused by such potentials.Test method provides accelerated conditions for cathodic disbondment to occur and provides a measure of resistance of coatings to this type of action.

CD tester is also used in civil engineering for evaluation of epoxy coated rebars to evaluate effect of cathodic protection.

CD Tester - is one of the useful instruments to test and determine accelerated corrosion testing.The instrument is highly user friendly and can be operated by technicians without any factory training. Cathodic disbondment instrument has connections made easy with plug and play devices.

In electrochemical process, a potentiostat is a controlled and measured device in an electrolytic cell, keeps the potential of the working electrode at a constant level with respect to the reference electrode.

It consists of an electric circuit which controls the potential across the cell by sensing changes in its resistance, varying accordingly the current supplied to the system: a higher resistance will result in a decreased current, while a lower resistance will result in an increased current, in order to keep the constant voltage.

CD Tester meets or exceeds the requirement:

ASTM G8, ASTM G42, ASTM G95, DIN 30671, EN 12068, ISO 15711, ISO 21809, NF A 49-710 /711 and CSA-Z245.20-06 Canadian spec.

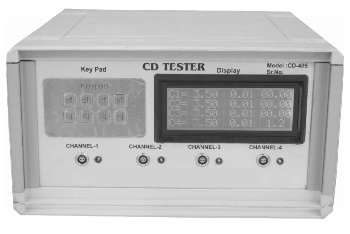

Unit consisting of: ( Model: CD - 405 )

-

◆ Multichannel CD Tester with 4 measuring channels.

-

◆ Automatic voltage regulation by microprocessor based circuit.

-

◆ Nominal adjustable voltage 0-4.00 V DC ±0.01 V, lc 0.01V Display 3 1/2 digit.

-

◆ Bright LED fitted to check working of channels within acceptable limits.

-

◆ On site calibration as per operating procedures.

-

◆ Display all settings and outputs of each channel.

-

◆ Selection of voltage via metallic keypad operation.

-

◆ 4 Acrylic glass test cups with cover to fit electrodes.

-

◆ 4 Sets of cable consisting platinum coated electrodes, Ag electrodes, working clamps.

-

◆ Power supply: 230 V/50 Hz, max. 30 W.

|